What are wire rope fittings?

Wire rope fittings are essential components in any system where wire ropes are used for lifting, rigging, anchoring, or securing loads. These fittings provide the necessary connection points between the wire rope and other elements in the system, ensuring both safety and reliability. Whether you’re working in construction, offshore environments, mining operations, or heavy industry, choosing the right wire rope fittings is essential for maintaining the integrity of the system under load.

What are wire rope fittings and what are they used for?

Wire rope fittings are mechanical or cast components used to terminate, join, tension, or guide wire ropes. They serve as the vital link between wire ropes and the equipment or structures they support. From lifting beams on a construction site to stabilizing cables on a bridge, wire rope fittings are engineered to handle extreme tension while allowing for either permanent or adjustable connections. These fittings must be precisely matched to their intended application, as the safety and longevity of the system depend heavily on the quality and suitability of the fitting.

Types of wire rope fittings

Wire rope fittings come in various forms, each with its own specific function and mechanical principle. At Global Rope Fittings, our AqualLine series includes a comprehensive range of fittings tailored to meet the diverse demands of different industries.

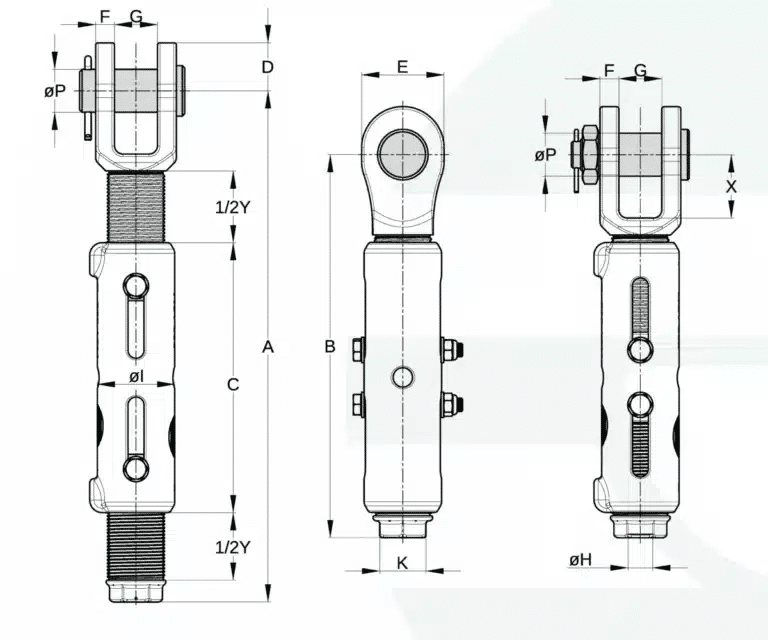

Spelter sockets:

Among the most commonly used types are spelter sockets, which are ideal for permanent terminations and ensure a maximum load-bearing capacity. These sockets are typically fixed using molten zinc or resin, creating a rigid and immovable connection.

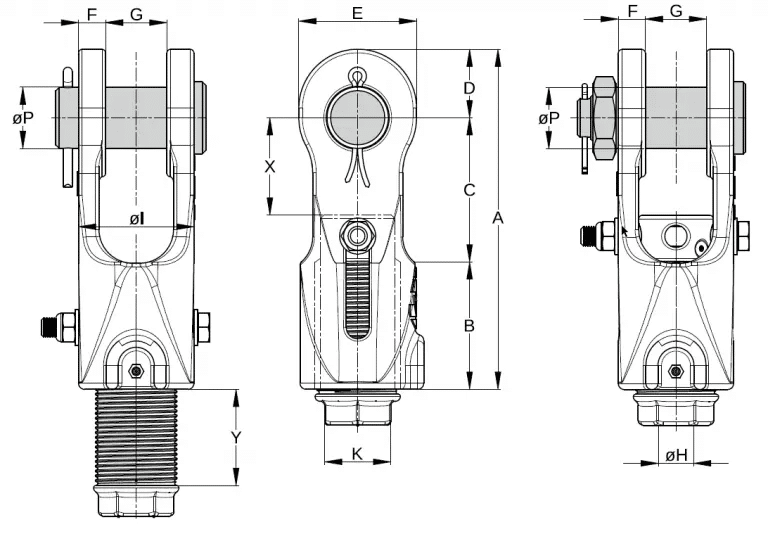

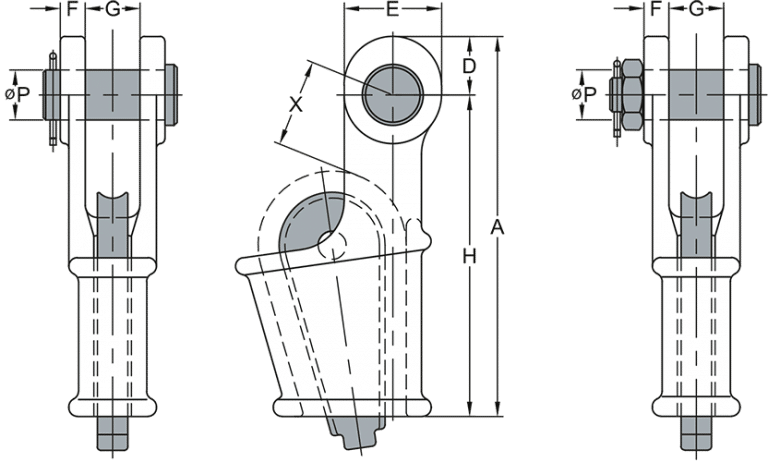

Wedge sockets:

In contrast, wedge sockets offer a more flexible solution, allowing the rope to be locked in place mechanically using a wedge. This design permits easier rope adjustments and reusability, making wedge sockets particularly useful for projects that require frequent changes in rope configuration.

Turnbuckle sockets:

Other types of wire rope fittings include turnbuckle sockets, which combine a socket with a threaded mechanism to provide controlled tensioning. These are widely used in architectural applications, cable-supported structures, and precision lifting systems.

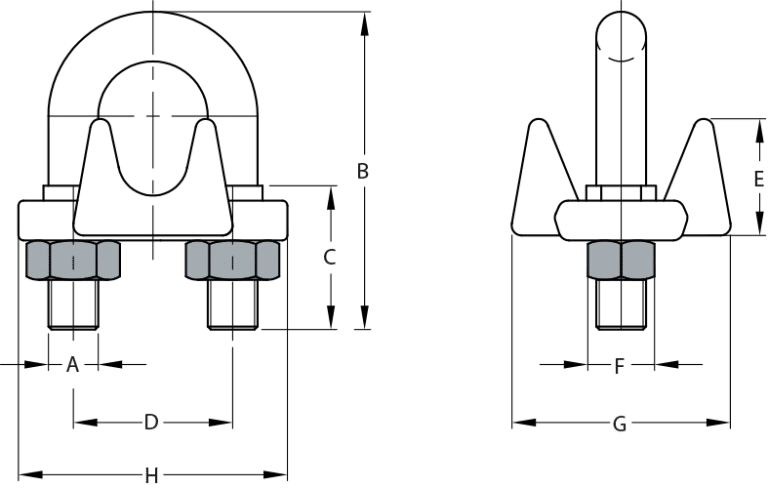

Thimbles, wire rope clips, and triangle plates:

Our AqualLine assortment also features lifting and rigging hardware such as thimbles, wire rope clips, and triangle plates, all of which contribute to guiding and reinforcing the wire rope in its designated role.

Custom fit:

For unique applications where off-the-shelf solutions do not suffice, we also offer custom-designed wire rope fittings that meet exact specifications in terms of material, dimension, and load rating.

Explore our full range of wire rope fittings

Applications of wire rope fittings

Our AqualLine wire rope fittings are used in virtually every sector that involves the movement, lifting, or securing of heavy loads. In the construction industry, they are essential for suspending structural components, anchoring frameworks, and operating cranes or hoists. Infrastructure projects such as bridges, stadiums, and rail networks rely on wire rope fittings to provide structural tension and stability. In marine and offshore environments, these fittings play a crucial role in mooring, towing, and lifting operations, where resistance to corrosion and dynamic loading is paramount.

The mining industry also heavily depends on wire rope fittings to connect equipment, support shafts, and lift heavy materials under extreme conditions. In ports and terminals, fittings are vital for cargo handling systems that must operate efficiently and safely under constant use. In the energy sector, especially in power transmission and wind energy, wire rope fittings ensure secure terminations and tensioned support for high-load cables. Heavy industry and manufacturing plants depend on them for material handling systems, overhead cranes, and safety-critical lifting equipment.

Across all these applications, the right fitting is not just a functional component,it is a critical safety element. From heavy lifting to precision adjustments, our wire rope fittings ensure performance and reliability in every scenario.

Discover a selection of projects where our products have been adopted

Why choose Global Rope Fittings for your wire rope fittings?

Wire rope fittings manufactured by Global Rope Fittings are engineered to meet the highest standards of safety, durability, and precision. Our AqualLine products are made from corrosion-resistant, high-strength materials that perform reliably even in the harshest environments. We understand that no two projects are the same, which is why our fittings are available in both standardized and customized versions to suit specific project requirements. Our team of specialists works closely with clients to ensure that all of our wire rope fittings match the operational and environmental conditions it will face, providing peace of mind and long-term reliability.

What sets our wire rope fittings apart is the rigorous testing each product undergoes. Every socket, clip, or termination is subject to quality checks and load tests that exceed industry norms. Our in-house engineering capabilities also allow us to innovate continuously, introducing new fitting types and improvements that reflect the evolving needs of the sectors we serve. When clients choose Global Rope Fittings, they are not just buying fittings,they are investing in trusted performance backed by years of technical expertise and customer support.

Our team of specialists is here to help you select the right wire rope fittings for your application.

Find the perfect wire rope fittings for your needs

How to select the right wire rope fittings

Choosing the correct wire rope fittings must be selected based on a combination of mechanical requirements and environmental conditions. It’s not just about whether a socket fits a specific rope diameter; it’s about whether that fitting will perform under the expected tension, resist corrosion in the working environment, and maintain its strength over time. Factors such as working load limit, frequency of rope replacement, exposure to moisture or chemicals, and the need for adjustability all play a role in selecting the correct wire rope fittings. For example, while spelter sockets may be appropriate for a permanent crane installation, a marine application may benefit more from wedge sockets that can be easily removed and inspected.

Clients often consult our technical team for guidance, especially when dealing with complex requirements such as dynamic loads, extreme temperatures, or the need to integrate the fitting into a larger mechanical system. We encourage this collaboration because it ensures optimal performance and safety. With the right wire rope fittings in place, operational risks are minimized, and equipment longevity is maximized.

The Global Rope Fittings wire rope fittings advantage

Wire rope fittings from Global Rope Fittings are more than components, they are solutions that solve real-world engineering challenges. With a commitment to innovation and customer-focused design, we deliver fittings that meet the specific demands of each industry we serve. Our focus on quality begins with material selection and extends through design, manufacturing, testing, and delivery. We take pride in helping our clients reduce downtime, improve safety, and achieve greater efficiency through fittings they can depend on.

From standard wedge sockets to custom-engineered thimbles, our wire rope fittings are trusted worldwide for a reason. When every connection counts, Global Rope Fittings delivers.

FAQs about wire rope fittings

What are wire rope fittings used for?

Wire rope fittings are used to terminate, connect, and adjust wire ropes in systems where safety and load control are critical, such as in lifting, anchoring, and rigging operations.

What is the difference between wedge sockets and spelter sockets?

Wire rope fittings like wedge sockets use a mechanical wedge to lock the rope in place and are reusable, while spelter sockets are permanent connections using molten zinc or resin.

Are wire rope fittings suitable for offshore environments?

Wire rope fittings from our AqualLine range are made from corrosion-resistant materials, making them ideal for marine and offshore use.

Can I reuse wire rope fittings?

Wire rope fittings such as wedge sockets can often be reused, provided they are regularly inspected and show no signs of wear, deformation, or corrosion.

Do you offer custom wire rope fittings?

Wire rope fittings can be custom-engineered by our team to meet specific load capacities, materials, and dimensions depending on your project needs.

Contact us for AqualLine wire rope fittings

Looking for high-performance wire rope fittings? Whether you need wire rope fittings, lifting and rigging hardware, or a custom solution, Global Rope Fittings is here to help. Contact us today for expert advice and tailored recommendations.

Reach out to our team now for your wire rope fittings