What is container handling?

Container handling plays a crucial role in global logistics, supporting the continuous movement of goods through ports, terminals, and intermodal transport systems. In these high-load, high-speed environments, every lifting operation depends on secure, reliable, and perfectly aligned connections between cranes, wire ropes, and container-lifting equipment. With safety and precision at the core of these operations, container handling systems must be equipped with components that can withstand forces, and constant environmental exposure.

At Global Rope Fittings, we engineer high-performance wire rope sockets and fittings designed specifically for the demands of container handling operations. From ship-to-shore cranes to automated stacking systems, our AqualLine products ensure stable, durable, and safe lifting connections where operational efficiency is non-negotiable.

Container handling refers to the lifting, moving, securing, and positioning of shipping containers using heavy-duty equipment such as quay cranes, mobile harbour cranes, reach stackers, straddle carriers, and terminal gantry cranes. These operations rely heavily on wire rope systems that must perform flawlessly under repeated cycles of lifting, lowering, and load transfer.

Efficient container handling relies on the reliability of every mechanical connection within the lifting system. Wire ropes, sockets, and rigging components are subjected to continuous tension, abrasion, and environmental exposure, making material strength and precision engineering essential.

Why container handling requires high-performance fittings

Container terminals operate around the clock, often in harsh and rapidly changing environments. Cranes and lifting systems must consistently deliver smooth, stable movement while carrying containers that can reach several tonnes in weight. This makes it essential that wire rope fittings offer not just strength, but also resistance to corrosion, fatigue, and variable loads.

Using reliable and precisely engineered fittings helps ensure proper rope alignment, controlled tension, and secure anchoring in every phase of the lifting cycle. This contributes directly to shorter handling times, reduced maintenance needs, and improved operational safety. For ports facing increasing throughput demands, the right fittings play a central role in maintaining performance and minimising downtime.

Container handling solutions by Global Rope Fittings

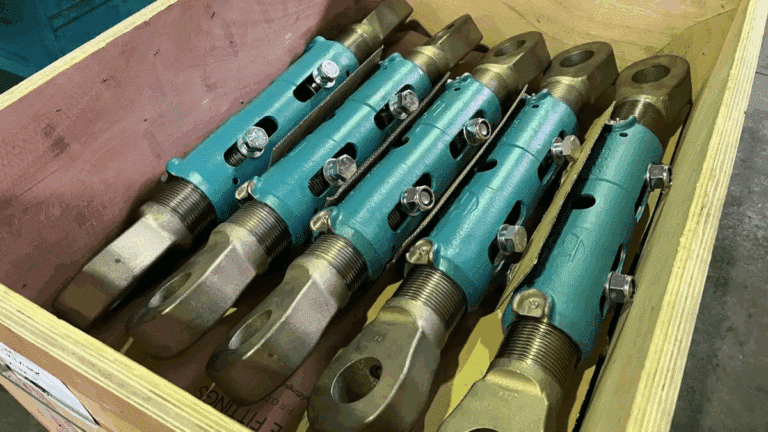

Global Rope Fittings supports container handling operations with a full range of AqualLine sockets and fittings engineered for high-load lifting applications. All products are manufactured from high-strength, corrosion-resistant materials that allow them to perform reliably in coastal environments, where humidity, salt exposure, and abrasive conditions are part of daily operations.

Our open spelter sockets, adjustable sockets (AOSS, ACTS, AOTS), turnbuckles (TBL-EJ, TBL-JJ, TBL-EE) and mobile harbour crane sockets are designed to provide secure wire rope terminations for both ship-to-shore and yard crane systems. Each component undergoes rigorous testing to ensure that safety and performance remain consistent throughout extensive lifting cycles. With short communication lines, rapid technical support, and fast delivery, we ensure that terminals can operate smoothly and efficiently, even during peak cargo movements.

Applications of container handling equipment

Container handling relies on a wide range of equipment, each requiring strong, durable, and precisely manufactured wire rope connections. In ship-to-shore crane operations, wire rope sockets play a key role in hoisting and trolley movement systems, ensuring that lifting equipment can manage the constant load changes that occur when transferring containers between vessels and shore.

Mobile harbour cranes and rubber tyre gantry cranes use high-performance fittings to stabilise and operate complex lifting systems under varying weather and load conditions. In automated container terminals, reliable wire rope fittings support the precise movement of cranes and spreaders that operate without manual intervention, making mechanical consistency essential.

Yard systems such as straddle carriers and reach stackers also depend on durable fittings to maintain the structural integrity of their lifting assemblies. Across all these applications, container handling requires fittings that combine mechanical strength with engineering precision to support continuous, safe, and efficient operation.

Wire rope fittings for container handling

Global Rope Fittings offers a specialised selection of fittings tailored for the demands of container handling environments.

- Open spelter sockets are widely used in crane hoisting systems for permanent, highly secure terminations that deliver maximum load-bearing strength.

- Adjustable sockets (AOSS, ACTS, AOTS) are used in container handling systems where precise length adjustment and controlled tensioning are required, allowing wire rope assemblies to be fine-tuned without dismantling the installation.

- Turnbuckles (TBL-EJ, TBL-JJ, TBL-EE) are applied in container handling equipment to maintain accurate tension and alignment in wire rope and rod systems.

- Mobile harbour crane sockets are engineered specifically for mobile harbour cranes, providing secure and durable wire rope terminations capable of withstanding high dynamic forces, frequent load changes, and harsh marine environments.

For port operators dealing with custom lifting arrangements or unique environmental challenges, our engineering team develops fully customised fittings. These solutions ensure compatibility with specific crane designs, rope diameters, load capacities, and terminal operational requirements.

How wire rope components support safe container handling

Wire rope sockets and fittings play a central role in the stability and performance of container handling equipment. Their primary function is to provide a secure termination point that transfers forces evenly through the wire rope assembly. Proper load distribution is essential in preventing premature wear, deformation, or failure of the rope.

The correct fitting ensures that tension remains consistent throughout repeated lifting cycles, even when cranes experience forces such as wind loads, vessel movement, or sudden changes in container weight. By maintaining rope integrity and alignment, these components help ensure safe lifting operations and extend the operational lifespan of both the wire rope and the crane.

Advantages of choosing Global Rope Fittings for operations

At Global Rope Fittings, safety, performance, and reliability form the foundation of every product we deliver. Our fittings are engineered to perform in the harshest maritime and industrial environments, using high-strength materials that resist corrosion and fatigue even under continuous use. Every component undergoes detailed inspection and testing, ensuring consistent performance in safety-critical lifting systems.

Our custom engineering capabilities allow us to support clients with solutions tailored to their unique terminal configurations, crane types, and operational requirements. Combined with our short response times, fast delivery, and dedicated technical support, we offer a dependable partnership for ports and industrial facilities where uninterrupted operation is essential.

FAQ about container handling

What is container handling?

Container handling refers to the lifting, moving, and securing of shipping containers using specialised equipment such as cranes, reach stackers, and automated handling systems.

Which wire rope fittings are commonly used in container handling?

Open spelter sockets, adjustable sockets (AOSS, ACTS, AOTS), turnbuckles (TBL-EJ, TBL-JJ, TBL-EE) and mobile harbour crane sockets are frequently used in crane hoisting systems, spreader operations, and support cable assemblies.

Why are high-strength fittings essential in container handling?

High-load lifting cycles, environmental exposure, and forces require fittings that offer strength, corrosion resistance, and long-term reliability.

Are fittings suitable for ship-to-shore and mobile harbour cranes?

Yes. Our AqualLine sockets and fittings are engineered specifically for heavy lifting operations in marine and industrial environments.

How do wire rope fittings enhance safety during container loading and unloading?

High-quality wire rope fittings support safe load transfer by maintaining secure terminations under varying loads and environmental stress. Engineered sockets ensure correct load distribution, minimize the risk of slippage, and support consistent performance throughout intensive lifting cycles. Every fitting undergoes rigorous testing to ensure reliability during critical container lifting operations.

Contact us for container handling solutions

Looking for reliable wire rope fittings engineered for container handling operations? From open spelter sockets to turnbuckles and fully custom solutions, Global Rope Fittings delivers components that enhance safety, efficiency, and operational performance. Get in touch with us.