What are thimbles for?

What are thimbles for?

Thimbles are essential components used in both wire and synthetic rope assemblies to protect the eye (the looped end) of the rope from wear, deformation, and abrasion. When ropes are looped around hooks, shackles, or other hardware, the area of the loop is most vulnerable to stress and friction. Thimbles reinforce this area, distributing the load more evenly and preserving the rope’s structural integrity.

By maintaining the original shape of the loop, thimbles minimize localized pressure and reduce the risk of the rope fraying, flattening, or breaking. In environments where ropes are subject to dynamic loading, movement, or harsh conditions (such as construction sites, offshore platforms, or maritime operations) thimbles are critical for ensuring both safety and longevity.

Whether you’re working with steel wire rope or synthetic rope, understanding how and when to use thimbles is crucial. They are more than just accessories; they are vital safety components in rigging, lifting, mooring, anchoring, and tensioning systems across countless industries.

Why choose our thimbles

At Global Rope Fittings, we understand that reliable thimbles are key to safe and efficient rope assemblies. That’s why our thimbles are engineered with precision and built from corrosion-resistant materials that can endure harsh environments, from saltwater and heavy industrial use, to cold weather and chemical exposure.

Each of our thimbles are designed to promote even load distribution across the rope loop. This prevents concentrated stress points, which can weaken or damage the rope over time. Our signature solid thimbles feature a wider radius and longer body than standard DIN 3091 models. This design allows the rope to bend more gradually over the thimble, significantly reducing the chance of the rope opening up or failing under pressure.

Thanks to their smart shape and high-quality finish, our thimbles are not only more durable, but also easier to install. Whether you’re incorporating them into lifting, rigging, or tensioning systems, they save time and minimize the margin for error. All of our thimbles are tested against industry standards, so you can trust their safety and performance, even in the most demanding environments.

Thimbles uses in different industries

Thimbles play a vital role across a wide variety of sectors. Their ability to reinforce loops and prevent rope damage makes them indispensable wherever cables are exposed to stress or movement.

In construction and infrastructure, thimbles are used in lifting slings, hoisting equipment, and suspension cables. They are often implemented in bridge construction and structural supports to provide stable, load-bearing connections.

In industrial settings, such as mining or manufacturing plants, thimbles protect the integrity of ropes used in cranes, pulleys, conveyor systems, and other heavy machinery. Here, they help absorb dynamic loads and protect against wear from repetitive motion.

In marine and offshore operations, thimbles are exposed to constant moisture, salinity, and movement. They’re essential in mooring lines, rigging, winches, and anchor systems, where rope reliability is critical for vessel safety and equipment operation.

Even in theatrical rigging and live event production, thimbles are used in overhead cable systems to support lights, set pieces, and sound equipment. In this context, precision and security are key to maintaining a safe working environment.

Each of our thimbles is rigorously tested to meet strict performance and safety standards, regardless of the application. Whether you’re working on land, at sea, or in controlled indoor environments, our products deliver proven results.

Discover a selection of projects where our products have been adopted

What type of thimbles exist?

There are two main categories of thimbles: standard/light-duty and heavy-duty.

Standard thimbles are designed for general-purpose applications that involve lower loads or less demanding conditions. They’re commonly used in recreational boating, small rigging setups, fencing systems, and light-duty lifting tasks. These thimbles are often made from materials such as galvanized steel, stainless steel, aluminum, or even high-grade plastic, depending on the environment. While they offer basic protection, they are not intended for high-tension or safety-critical applications.

Heavy-duty thimbles, on the other hand, are built for the toughest jobs. These are the go-to choice for industrial lifting, marine rigging, offshore anchoring, and high-load tensioning systems. Made from reinforced materials such as forged carbon steel or marine-grade stainless steel, they are designed to handle extreme pressure, repeated dynamic motion, and exposure to corrosive elements. Their robust shape and material composition ensure consistent performance under stress and minimize the risk of failure.

Choosing the right type of thimbles depends on your rope diameter, load requirements, environmental conditions, and safety protocols.

Types of thimbles we offer

At Global Rope Fittings, we supply a versatile range of thimbles that meet the technical and operational needs of various industries and use cases.

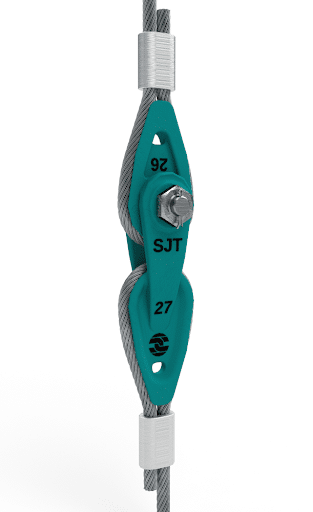

Our solid heavy-duty thimbles are designed to withstand extreme loads. With their reinforced build and optimized geometry, they provide maximum rope protection, even in the most hostile working conditions.

We also offer wire thimbles and clamp sets, combining the thimbles with a compatible clamp to ensure complete loop termination. These sets are ideal when efficiency and ease of assembly are essential, as they reduce installation time while improving loop strength.

For clients with unique requirements, our custom thimbles are the ideal solution. Whether you need a thimble for a non-standard rope size, a specific material for corrosive environments, or a particular design feature, we can engineer a product to fit your exact needs.

All of our thimbles, whether standard or bespoke, are subjected to thorough quality checks and testing procedures before they leave our facility.

Why choose Global Rope Fittings for your thimbles?

When it comes to critical rope components like thimbles, experience and attention to detail matter. At Global Rope Fittings, we combine engineering excellence with a deep understanding of field requirements. Our thimbles are the result of decades of expertise in wire rope fittings and mechanical load management.

We use only premium-grade materials, and our products are manufactured to meet or exceed international safety and quality standards. Our team works closely with clients to deliver tailored solutions, whether that means a high-volume supply of standard thimbles or the development of custom components for complex lifting and rigging systems.

Choosing Global Rope Fittings means choosing reliability, precision, and a partner who understands the importance of every connection in your operation.

FAQs about thimbles

What is the purpose of a thimble in a rope assembly?

A thimble protects the looped end of a rope from wear, abrasion, and deformation. It maintains the shape of the loop and ensures even load distribution, which helps extend the lifespan of the rope and increases safety under tension.

Are thimbles only for wire ropes, or can they be used with synthetic ropes too?

Thimbles can be used with both wire and synthetic ropes. While they are most commonly seen in steel wire rope applications, they are also effective in protecting synthetic rope loops in lighter-duty or recreational systems.

How do I know which type of thimble I need?

The right thimbles depend on your application. Consider the rope diameter, expected load, environment (e.g., marine, industrial), and whether the use is temporary or permanent. Standard thimbles are sufficient for basic tasks, while heavy-duty thimbles are required for high-load or safety-critical environments.

Do thimbles require specific tools for installation?

Thimbles themselves don’t require special tools, but they are typically used in conjunction with clamps or ferrules, which do. For proper installation and safety, we recommend working with trained rigging professionals — especially in load-bearing systems.

Can I get a custom thimbles made for a specific project?

Yes, Global Rope Fittings offers custom-engineered thimbles tailored to your technical specifications. We can adapt the size, material, and design to meet unique project requirements and environmental conditions.

Are your thimbles certified or tested?

Absolutely. All our thimbles undergo rigorous quality control and are tested to meet relevant industry standards. Certifications and documentation can be provided on request, especially for safety-critical or offshore applications.

Contact us for thimbles

Looking for reliable thimbles for your rope applications? Whether you need standard, heavy-duty, or custom solutions, we are here to help. Contact our team for expert guidance and tailored recommendations on thimble uses.