What is industrial lifting equipment?

Industrial lifting equipment refers to the essential components used to lift, secure, tension, and control heavy loads across demanding industrial environments. Engineered to withstand extreme forces, dynamic loads, and complex operational conditions, industrial lifting equipment ensures safe and efficient performance where reliability is critical. From offshore lifting systems to crane operations and large-scale construction projects, lifting equipment forms the backbone of safe and controlled material handling.

High-quality lifting equipment is indispensable in environments where every connection must perform flawlessly. Whether you are working with wire ropes, heavy-duty lifting assemblies, or structural tension systems, the right equipment enhances operational safety, minimizes downtime, and ensures long-term system performance.

Why industrial lifting equipment is essential for your operation

Industrial lifting equipment is designed to deliver maximum safety, efficiency, and durability. Industrial lifting equipment supports critical load handling tasks from the moment it is installed and plays a vital role in maintaining stability, alignment, and controlled tension under high-load conditions.

Key benefits:

- Enhanced safety thanks to secure load transfer and engineered load paths

- Operational efficiency with quick installation and minimal maintenance

- Compatibility with wire ropes, steel cables, and lifting assemblies

- Flexibility for lifting, securing, tensioning, and supporting heavy structures

- Durability engineered to withstand corrosion, abrasion and vibration.

Reliable lifting equipment helps prevent slippage, misalignment, or overloading. This ensures safe, predictable performance in critical operations.

Industrial lifting equipment by Global Rope Fittings

At Global Rope Fittings, our lifting components are engineered with precision and designed for extreme environments. From turbulent offshore conditions to high-load crane systems, our AqualLine products deliver strength, reliability, and long-term performance.

Every component is manufactured using high-strength, corrosion-resistant materials and undergoes rigorous testing to meet or exceed the highest industry standards. With decades of engineering experience, we support customers with both standard and fully custom solutions tailored to their specific lifting requirements.

Applications of industrial lifting equipment

Industrial lifting equipment is used wherever safety, precision, and reliability are mission-critical. For real-world examples of how our products perform in demanding environments, explore our projects.

Construction & Infrastructure

- Lifting and stabilizing structural elements

- Supporting bridges, stadiums, and large frameworks

- Ensuring reliable load-bearing performance in lifting systems

Marine & Offshore

- Supporting offshore crane operations

- Securing mooring and subsea structures

- Performing in turbulent, corrosive marine conditions

Cranes & Lifting Systems

- Safe load transfer during heavy lifting operations

- Ensuring alignment and tension in crane wire ropes

- Optimizing reliability within lifting assemblies

Mining & Heavy Industry

- Supporting high-load material transport systems

- Stabilizing cables and anchor points in rugged environments

- Delivering consistent performance under dynamic and abrasive conditions

Wherever extreme loads and challenging environments are involved, industrial lifting equipment ensures safe and efficient operation.

Types of industrial lifting equipment we offer

Global Rope Fittings provides a comprehensive range of lifting components designed to meet diverse mechanical and environmental requirements across industries.

Wire rope sockets

Wire rope sockets offer permanent or adjustable terminations for maximum load control and safety. Typical solutions include AqualLine open spelter sockets for permanent, high-load terminations and AqualLine open wedge sockets for applications requiring adjustability and quick installation.

- Extreme load-bearing capacity

- Permanent or re-adjustable connection options

- Suitable for construction, offshore, and crane applications

Lifting & rigging hardware

Rigging hardware connects and stabilises wire rope systems with high-strength components designed for heavy-duty applications. Typical examples include AqualLine solid wire rope thimbles, which protect rope eyes against wear and deformation, and AqualLine heavy duty triangle plates, used to distribute loads evenly across multiple connection points within rigging assemblies.

- Reliable connections

- Optimized load distribution

- Essential for structural and lifting systems

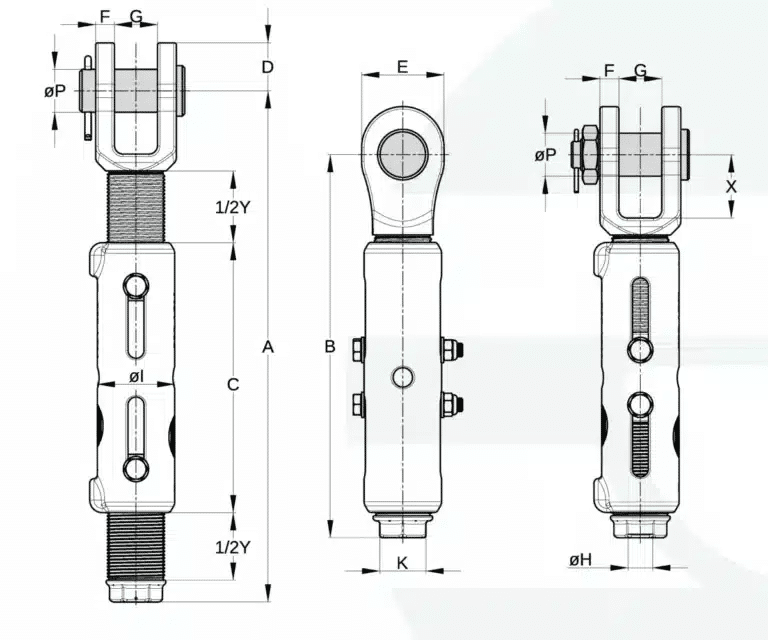

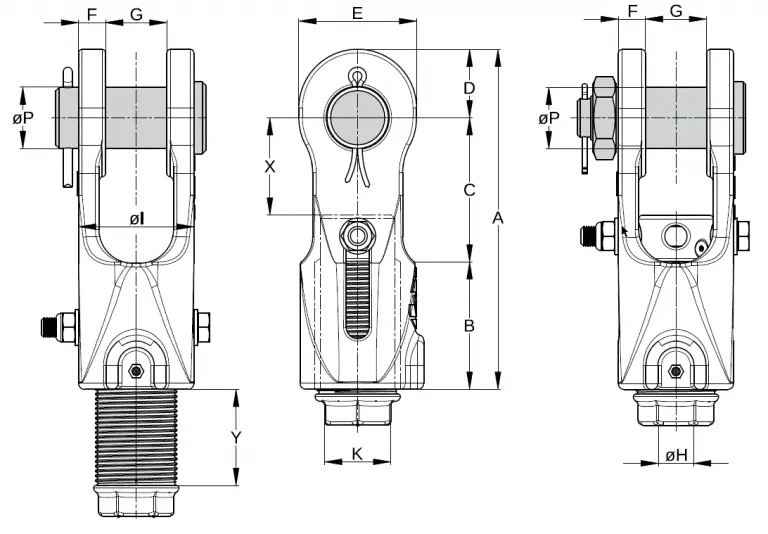

Adjustable sockets

Turnbuckles sockets combine the strength of sockets with precision tension adjustment required for structural and lifting systems.

Global Rope Fittings supplies adjustable turnbuckle sockets in both open configurations for accessible connections and closed configurations for applications where enhanced security and long-term stability are essential.

- Controlled tensioning

- Wide compatibility

- Engineered for high-load conditions

Turnbuckles

Turnbuckles are mechanical tensioning components used to adjust the length and tension of rigging assemblies. Unlike adjustable sockets, turnbuckles connect directly to threaded fittings such as eyes, forks, or jaw ends, making them ideal for applications where flexibility, adjustment, or disassembly is required.

Global Rope Fittings supplies turnbuckles in multiple configurations to suit different connection requirements:

Custom-made rigging hardware

For unique lifting challenges or non-standard dimensions, we engineer fully custom solutions.

- Specialized materials for extreme environments

- Full engineering support from concept to installation

How industrial lifting equipment works in lifting systems

Industrial lifting equipment functions as the essential connection, support and load-transfer interface within lifting assemblies. Each component plays a crucial role in enabling safe, controlled and efficient load handling. By distributing forces evenly across the system, lifting equipment helps reduce stress, vibration and rope wear while maintaining precise alignment throughout the lifting process.

Whether used in permanent or adjustable configurations, these components enhance the stability and predictability of the entire installation. Through engineered load control and consistent performance, industrial lifting equipment ensures that lifting, suspending, securing and tensioning operations can be carried out safely, even under demanding conditions.

Advantages of industrial lifting equipment by Global Rope Fittings

Global Rope Fittings delivers lifting components engineered for high-performance environments, supported by unmatched service and technical expertise.

Engineered for extreme environments: Designed for offshore storms, heavy industrial loads, and corrosive marine conditions, where every connection counts.

Premium materials: High-strength steel and corrosion-resistant alloys ensure long-term durability and stability under extreme loads.

Rigorous testing & certification: Every product undergoes extensive testing to meet stringent global standards.

Tailored solution: We provide custom-engineered lifting components for complex or unique technical requirements.

FAQs about industrial lifting equipment

What is industrial lifting equipment used for?

Industrial lifting equipment is used to lift, secure, tension, and support heavy loads in construction, offshore, mining, and crane operations.

What components fall under industrial lifting equipment?

Components such as wire rope sockets, rigging hardware, turnbuckles, and custom lifting fittings are commonly used in industrial lifting systems.

Is industrial lifting equipment suitable for offshore use?

Yes. Our AqualLine components are made from corrosion-resistant, high-strength materials engineered for marine and offshore environments.

Can industrial lifting equipment be reused?

Some components, such as wedge-style fittings, can be reused with proper inspection. Permanent terminations like spelter sockets should not be reused.

Do you offer custom lifting components?

Absolutely. We engineer custom lifting solutions for complex applications, special dimensions, and extreme environmental conditions.

How do I determine the correct lifting equipment for my wire rope system?

Selecting the right industrial lifting equipment depends on factors such as load capacity, rope diameter, environmental conditions, frequency of use, and whether the termination must be permanent or adjustable. Our engineering team can support you with expert advice based on your project requirements.

What certifications should industrial lifting equipment comply with?

High-quality lifting components should meet international safety and performance standards. All AqualLine products undergo rigorous testing and comply with globally recognized certifications to ensure safe and reliable operation in demanding environments.

Contact us for industrial lifting equipment

Looking for high-performance industrial lifting equipment? Whether you need standard lifting components or a fully custom solution, our team is ready to support your project. Contact us for your industrial lifting equipment.