What is industrial lifting equipment?

Industrial rigging equipment refers to the essential components used to secure, lift, stabilize and control heavy loads across demanding industrial environments. Designed to perform under extreme forces and changing conditions, industrial rigging equipment ensures safe and efficient operation wherever reliability is critical. From offshore platforms and heavy-lift cranes to construction sites and mining operations, rigging equipment forms the foundation of controlled, dependable material handling.

High-quality rigging solutions are indispensable in environments where every connection must perform flawlessly. Whether you work with wire ropes, tensioning systems or complex multi-leg assemblies, the right equipment improves safety, minimizes downtime and supports long-term operational performance.

Why industrial rigging equipment matters for your operation

Industrial rigging equipment is engineered to deliver consistent strength, stability and safety. Industrial rigging equipment directly supports secure lifting and load transfer, reducing the risk of misalignment, slippage or structural stress. By ensuring controlled tension and stable load paths, rigging equipment plays a critical role.

It enhances efficiency by allowing operators to work with dependable components that maintain performance under corrosion, vibration and harsh environmental exposure. For industries where downtime is costly and safety standards are high, reliable rigging equipment is essential.

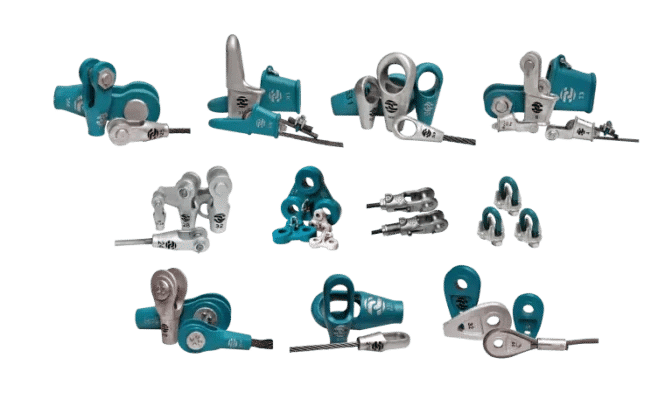

Industrial rigging equipment by Global Rope Fittings

At Global Rope Fittings, all rigging components are engineered with precision and designed for extreme industrial conditions. Our AqualLine products deliver long-lasting strength and reliability, whether used in turbulent offshore environments, high-load crane systems or heavy industrial operations.

With high-strength, corrosion-resistant materials and rigorous testing procedures, our rigging equipment meets or exceeds international standards. We also support clients with custom-engineered solutions, ensuring that each component aligns with specific operational, dimensional or environmental requirements.

Applications of industrial rigging equipment

Industrial rigging equipment is used in sectors where safe load handling, tension control and structural stability are essential. In construction and infrastructure projects, rigging components secure structural elements, support cranes and stabilize lifting systems. Offshore and marine operations depend on rigging equipment that tolerates corrosive environments, fluctuating loads and continuous movement.

Cranes and heavy lifting systems rely on precise alignment and secure terminations to maintain operational safety, while mining and heavy industry require rugged components that withstand abrasive conditions and intense mechanical stress. Wherever heavy loads must be lifted, guided or secured, industrial rigging equipment ensures predictable, efficient and safe operation.

Types of industrial rigging equipment we offer

Global Rope Fittings supplies a comprehensive range of rigging components tailored to the demands of heavy industry. Wire rope sockets provide secure, permanent or adjustable terminations for rigging systems, ensuring reliable load transfer in lifting, mooring, and structural applications.

For projects requiring precise alignment and controlled tension, we offer advanced adjustable socket solutions, including adjustable open turnbuckle sockets, adjustable closed turnbuckle sockets, and adjustable open spelter sockets. These components enable fine-tuned length adjustment while maintaining high load capacity and long-term reliability.

Additional rigging hardware, such as plates, connectors, turnbuckles and other tensioning elements, contributes to the stability and structural integrity of assemblies used in offshore platforms, crane systems, and construction projects. Where standard fittings are insufficient, our custom-made components address unique technical challenges through optimized design, material selection, and load performance.

How industrial rigging equipment enhances system performance

Industrial rigging equipment functions as the essential connection and support interface within rigging assemblies. By distributing forces safely, reducing vibration and maintaining alignment, these components contribute directly to predictable load handling. Adjustable or permanent terminations allow systems to perform reliably under variable loads. This integrated performance ensures that lifting, stabilizing and tensioning operations remain safe and efficient even in the harshest industrial environments.

Industrial rigging equipment also plays an important role in extending the lifespan of wire ropes and related lifting systems. By ensuring that forces are transferred evenly and by minimizing friction and vibration, well-engineered rigging components help prevent premature wear and unexpected failures. This contributes not only to safer operations but also to greater cost-efficiency over time, as systems require fewer replacements, fewer stoppages and less corrective maintenance. In industries where continuity and predictability are crucial, the quality of rigging equipment directly influences overall operational performance.

The advantages of choosing Global Rope Fittings

Global Rope Fittings delivers rigging components engineered for extreme environments, backed by decades of technical expertise. Our products are crafted from premium materials selected for strength and corrosion resistance, ensuring long-term durability even under heavy stress. Every component undergoes rigorous testing to guarantee compliance with international safety and performance standards. For complex or highly specialized applications, we provide custom-engineered solutions tailored to specific project needs.

FAQs about industrial lifting equipment

What is industrial rigging equipment used for?

Industrial rigging equipment is used to lift, secure, stabilize and tension heavy loads in construction, offshore, mining and crane operations.

What components are included in industrial rigging equipment?

Wire rope sockets, rigging hardware, tensioning components and custom fittings are commonly used in industrial rigging systems.

Is industrial rigging equipment suitable for offshore environments?

Yes. Our AqualLine components are engineered from corrosion-resistant materials suitable for marine and offshore applications.

Can rigging equipment be reused?

Reusable components such as wedge-based fittings can often be used again after proper inspection. Permanent terminations, such as spelter sockets, should not be reused.

Do you offer custom rigging solutions?

Absolutely. We design and manufacture custom rigging components for specialized load ratings, environmental conditions or project-specific dimensions.

How do I select the right rigging equipment for my application?

Selection depends on factors such as load requirements, rope diameter, environmental exposure and the need for permanent or adjustable terminations. Our technical team provides tailored advice.

What certifications should rigging equipment comply with?

Industrial rigging equipment should meet internationally recognized safety and performance standards. All AqualLine components undergo rigorous testing to ensure full compliance.

What factors influence the lifespan of industrial rigging equipment?

The lifespan of industrial rigging equipment is influenced by load cycles, environmental exposure, maintenance frequency and the type of forces applied during operation. Components exposed to saltwater, abrasive conditions or continuous changing loads may require more frequent inspection or earlier replacement. Using high-quality materials, ensuring correct installation and performing regular maintenance all contribute significantly to extending the operational life of rigging equipment.

Contact us for industrial rigging equipment

Looking for high-performance industrial rigging equipment? Whether you require standard components or a fully custom solution, our team is ready to support your project. Contact us for your industrial rigging equipment.