Rigging fittings are essential components in lifting, securing, and tensioning wire ropes and steel cables. These specialized fittings serve as the connection points between wire ropes and the structures or loads they support, ensuring optimal safety, efficiency, and durability. From heavy construction to offshore operations and transport, rigging fittings play a vital role in various industrial applications.

Types of rigging fittings we offer

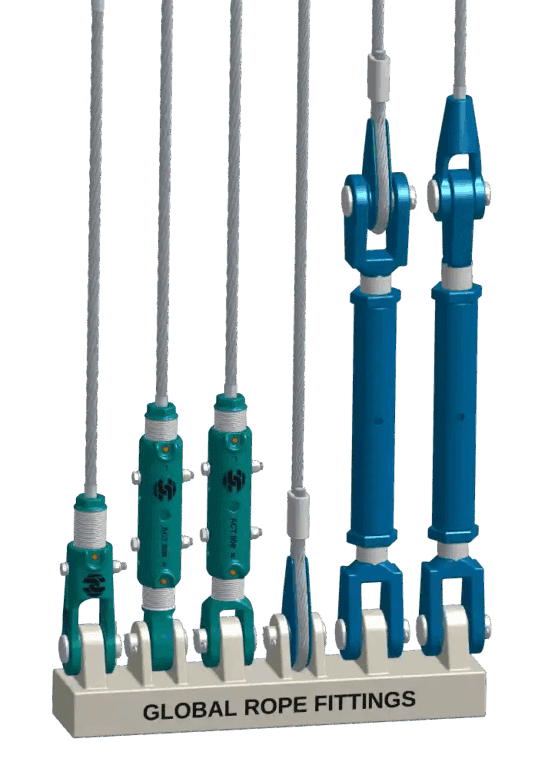

Rigging fittings come in different shapes and sizes, each designed for specific functions. At Global Rope Fittings, we provide a diverse range of rigging solutions: our AqualLine range, to meet your unique needs, all ‘Designed to Perfection’:

Adjustable turnbuckle sockets

○ Specialized rigging components designed to provide fine-tuned tension adjustment in wire rope systems. They combine a socket with a turnbuckle mechanism, allowing for controlled length adjustment and tensioning, providing precise control in rigging applications.

○ Within our AqualLine assortment we have adjustable open and closed turnbuckle sockets.

Spelter and wedge sockets

○ Used to connect the end of a wire rope to a rigging component. Designed for durability and strength, rigging sockets prevent fraying while ensuring a safe and solid connection.

○ We offer spelter sockets in a wide array of types, including open spelter sockets, closed spelter sockets, anchor pendant sockets, mobile harbour crane sockets, open strand spelter sockets, open DIN sockets and open JIS sockets.

○ Our options for wedge sockets include open wedge sockets, open wedge sockets with an integrated tail clamp and closed wedge sockets.

Rigging hardware

○ Wire rope accessories that are used to secure, guide, or reinforce wire rope fittings in rigging applications.

○ Available rigging hardware includes wire rope clips, heavy duty triangle plates and solid wire rope thimbles.

Custom rigging fittings

○ Tailored solutions designed for unique project requirements, available in custom sizes, coatings, and materials. Custom rigging fittings are engineered for extreme loads and specialized industrial needs. Our custom fittings provide reliability where standard options fall short.

Find the perfect rigging fittings for your product.

Why choose our rigging fittings?

At Global Rope Fittings, we are dedicated to delivering rigging fittings that not only meet but exceed the expectations of our customers. As a true wire rope fittings specialist, our AqualLine rigging fittings are engineered for long-term performance, even in the most demanding environments. Built from premium-grade materials, they are designed to endure harsh weather, corrosive conditions, and extreme mechanical stress without compromising on strength or reliability. This durability makes them an ideal choice for both temporary operations and permanent installations.

Ease of installation and low-maintenance design are equally important to us. Our fittings are developed to simplify rigging processes, minimize downtime, and increase on-site efficiency, saving both time and labor costs. Whether used in dynamic offshore operations, large-scale infrastructure projects, or everyday lifting tasks, our fittings integrate seamlessly into existing systems and deliver consistent performance.

We also understand that no two projects are the same. That’s why we offer a broad and adaptable range of rigging fittings to suit a wide variety of industries – from construction and civil engineering to maritime, offshore energy, and heavy-duty transport. Each product is designed with versatility in mind, giving engineers and operators the freedom to create safe and efficient rigging systems tailored to their exact requirements.

Above all, safety is at the core of everything we do. All of our rigging fittings are manufactured in compliance with internationally recognized standards and undergo rigorous quality control procedures to ensure absolute reliability.

Find the perfect rigging fittings for your project

Choosing the right rigging fittings depends on several factors, including the type and diameter of the wire rope, the load requirements, the environmental conditions, and the specific application. For example, high-load lifting operations might require spelter sockets or heavy duty thimbles, while temporary installations might use wedge sockets and U-bolt wire rope clips. It’s also important to ensure that all components are compatible and rated for the same load to avoid failure under stress.

Selecting the right rigging fittings is crucial for the safety and success of your operations. Whether you need standard fittings or customized solutions, our team at Global Rope Fittings is here to help. Contact us today for expert advice and tailored recommendations to meet your specific needs.

Frequently asked questions about rigging fittings

Are rigging fittings standardized?

Yes, many rigging fittings follow international standards such as those set by ISO, ASTM, or EN. These standards define critical specifications like material strength, design tolerances, load ratings, and safety factors. Standardization ensures that fittings perform consistently and safely across different projects and equipment. However, custom fittings are sometimes required for unique applications that fall outside standard parameters.

Can rigging fittings be reused?

In some cases, rigging fittings can be reused, especially if they show no signs of deformation, corrosion, or wear. However, it’s strongly recommended to always inspect all components thoroughly and follow industry guidelines. For maximum safety, especially in load-bearing systems, fittings should either be replaced regularly or tested according to applicable safety standards.

What materials are rigging fittings made from?

Rigging fittings are typically made from high-strength materials such as forged steel, stainless steel, or galvanized steel. The choice of material depends on the environment in which they’ll be used. For example, stainless steel is ideal for marine or corrosive environments due to its resistance to rust and degradation, while galvanized steel offers a cost-effective option for general use. In high-performance or offshore settings, alloy steels with additional coatings may be used to enhance durability under extreme stress.

Are there safety guidelines for using rigging fittings?

Yes, using rigging fittings safely requires adherence to specific guidelines. It’s important to never exceed the working load limit (WLL) of any component and to ensure that fittings are properly installed and aligned. Misuse – such as over-tightening, side loading, or mixing incompatible components – can result in failure or serious accidents. Regular inspections, proper storage, and staff training are all part of a safe rigging practice.

Where are rigging fittings commonly used?

Rigging fittings are used in a wide range of industries, including construction, shipbuilding, offshore oil and gas, transport, and even architecture. They are crucial in operations such as crane lifting, structural cable support, bridge suspension systems, and securing heavy loads during transport. Essentially, wherever wire ropes are used to support, lift, or secure loads, rigging fittings play a central role in ensuring those connections are strong and safe.

Contact us for rigging fittings

Have questions or need assistance selecting the right rigging fittings? Our experts are ready to help. Get in touch with us today and find the perfect solution for your rigging needs.

Want more information or help with rigging fittings? Get in touch with us