What are rigging turnbuckles?

Rigging turnbuckles are precision-engineered tensioning devices used to adjust and maintain the correct tension in wire rope systems, ensuring stability, safety, and long-term performance across demanding industrial environments. Designed to withstand extreme loads and dynamic conditions, rigging turnbuckles are essential components in structural installations, lifting operations, marine systems, and heavy-duty rigging applications.

As part of high-performance wire rope assemblies, turnbuckles allow operators to fine-tune rope tension with accuracy, improving operational efficiency while maintaining maximum safety. Whether used in crane rigging, offshore structures, or architectural cable systems, turnbuckles deliver reliable tension control where every connection must perform flawlessly.

Why choose rigging turnbuckles for your project?

Rigging turnbuckles offer a unique combination of adjustability, load control, and operational precision. Immediately after installation, the threaded design enables controlled tensioning without dismantling the system, making turnbuckles indispensable for applications where exact cable positioning and safe load distribution are required.

Key benefits include:

- Precision tension adjustment for structural systems under predominantly static loads and moderate load variations (e.g. wind).

- High load-bearing capability, engineered for demanding environments

- Compatibility with wire ropes, rods, and galvanised steel cables

- Long-lasting reliability due to corrosion-resistant, high-strength materials

- Versatility across marine, industrial, and construction applications

Turnbuckles help prevent slack, vibration, and misalignment. This is critical in environments where stability directly influences operational safety.

Rigging turnbuckles by Global Rope Fittings

At Global Rope Fittings, rigging turnbuckles are engineered with the same commitment to durability, efficiency, and safety that defines our entire AqualLine product range. Every component is designed to perform in the harshest environments, whether exposed to saltwater, mechanical stress, or fluctuating loads.

Our turnbuckles are crafted using high-strength alloy cast steel and advanced manufacturing techniques, ensuring long-term performance in critical applications. Whether your operation demands fine-tuned structural tension, secure anchoring, or stable performance under predominantly static and variable loading conditions, our rigging turnbuckles deliver dependable results supported by our technical expertise.

Applications of rigging turnbuckles

Rigging turnbuckles are used across industries where safety, strength, and precise control are essential. For an impression of real-world use cases, explore our projects and applications. Common applications include:

Construction & Infrastructure

- Tensioning architectural cables

- Stabilizing structural frameworks

- Ensuring secure anchorage for bridges, roof systems, and high-load assemblies

Marine & Offshore

- Adjusting mooring lines

- Securing offshore platforms

- Tensioning marine rigging exposed to corrosive environments

Cranes & Lifting Systems

- Maintaining correct cable tension

- Ensuring alignment and stability in lifting operations

- Preventing slack in wire rope systems

Mining & Heavy Industry

- Tensioning support cables

- Maintaining stability in vertical and horizontal load-bearing systems

- Managing variable loads in harsh environmental conditions

Wherever reliability under pressure is essential, rigging turnbuckles provide the precision and resilience needed to operate safely.

Types of rigging turnbuckles we offer

Global Rope Fittings provides a complete selection of rigging turnbuckles, each engineered for specific operational and load requirements.

Open-body turnbuckles

The AqualLine open-body turnbuckles are jaw-jaw turnbuckles that offer a direct clevis-style connection on both ends, allowing fast installation without additional hardware. This design provides a secure, non-rotating attachment, ideal when a firm and stable connection is required.

Closed-body turnbuckles

Our AqualLine closed-body turnbuckles are eye-eye turnbuckles that provide universal compatibility, as each eye can be connected using shackles, bolts, or links. This offers greater flexibility in orientation and movement, making it easy to integrate into various tensioning systems.

Mixed-body turnbuckles

An AqualLine eye–jaw turnbuckle combines the versatility of an eye with the direct pin connection of a jaw. This mixed configuration is ideal when one side requires flexible linking while the other needs a secure, fixed attachment point.

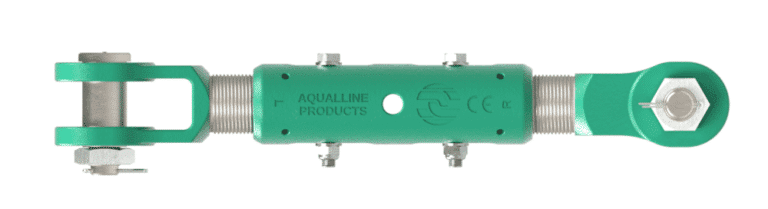

Turnbuckle sockets

AqualLine open and closed Turnbuckle Sockets feature a hybrid design that integrates a high-strength spelter socket with an adjustable body, providing both wire-rope termination and smooth, reliable tensioning. This combined construction reduces the number of separate components and ensures a compact, stable, and easy-to-maintain solution for any tensioning system.

Custom-made turnbuckles

For non-standard load ratings, large diameters, or specific environmental conditions, we design custom-engineered AqualLine turnbuckles in collaboration with your project team.

How rigging turnbuckles work

Rigging turnbuckles operate using two threaded end fittings, typically eye, jaw, or socket configurations, connected by a central frame. By rotating the central body, operators can increase or decrease tension with precision.

How the mechanism enhances performance:

- Clockwise rotation shortens the assembly, increasing tension

- Counterclockwise rotation lengthens it, reducing tension

- The threaded design provides controlled, gradual adjustment

- Mechanical advantage allows significant tension change with minimal effort

This mechanism is essential for maintaining structural integrity, especially in systems exposed to variable loads, temperature changes, or vibration.

Advantages of using rigging turnbuckles by Global Rope Fittings

At Global Rope Fittings, our rigging turnbuckles reflect our commitment to engineering excellence, service, and safety:

Engineered for extreme environments

Designed to perform in the harshest offshore, industrial, and marine conditions, where every connection counts.

Premium materials & corrosion resistance

Only high-strength alloy cast steel and corrosion-resistant alloys are used, ensuring long-lasting durability even under heavy loads.

Rigorous testing

Every turnbuckle undergoes strict quality control in line with the standards applied to all AqualLine products.

Custom solutions for complex challenges

With decades of engineering experience, we provide bespoke designs tailored to your technical specifications.

Fast response & delivery

As with all our fittings, we offer:

- Response within 24 hours

- Fast delivery

- Technical support throughout your project

FAQs about rigging turnbuckles

What are rigging turnbuckles used for?

Rigging turnbuckles are used to tension, adjust, and secure wire rope assemblies in construction, marine, industrial, and lifting operations. They allow precise control over cable tension and alignment.

What is the difference between open-body and closed-body turnbuckles?

Open-body turnbuckles offer a fixed jaw-jaw connection for stable, non-rotating setups. Closed-body turnbuckles feature an eye-eye design that allows flexible linking with shackles or bolts, making them easier to integrate into diverse tensioning systems.

Are rigging turnbuckles suitable for offshore use?

Yes. Our turnbuckles are engineered using high-strength, corrosion-resistant materials suitable for offshore, marine, and port environments.

Can turnbuckles be used with wire rope sockets?

Yes. Turnbuckles can be used with wire rope sockets, and for this purpose we offer a dedicated AqualLine range of turnbuckle sockets. This product line includes several configurations, designed to provide precise tension adjustment in wire-rope systems used across lifting, marine, and structural applications.

Can I order custom-made rigging turnbuckles?

Yes. We offer custom-engineered turnbuckles designed according to your load requirements, cable diameters, and environmental conditions.

Do rigging turnbuckles require maintenance?

Yes. To ensure long-term safety and performance, turnbuckles should be inspected regularly for corrosion, thread wear, misalignment, or deformation. In high-load or offshore environments, more frequent inspections are recommended. Proper lubrication of the threads can also extend service life and maintain smooth operation.

Contact us for rigging turnbuckles

Looking for high-performance rigging turnbuckles engineered for demanding applications? Whether you need standard open-body or closed-body turnbuckles, socket-integrated designs, or a fully customized solution, our team is here to assist you with technical guidance and tailored recommendations. Get in touch with us.