Stainless steel thimbles are vital components in wire rope assemblies, specifically engineered to protect the eye or loop of a rope from wear, deformation, and corrosion. Stainless steel thimbles are crafted from stainless steel, a material known for its excellent resistance to rust, chemicals, and extreme weather conditions. This makes them ideal for demanding environments where both mechanical strength and environmental durability are required.

When a rope is looped around a hook, shackle, or other termination hardware, it is exposed to stress at the point of contact. Stainless steel thimbles help preserve the shape of the loop and prevent the rope from pinching or fraying under tension. This protection is critical not only for the rope’s performance but also for overall safety in lifting, mooring, and rigging operations.

Their use is widespread across industries that rely on secure and long-lasting rope assemblies, from marine and offshore installations to construction sites, heavy equipment handling, and agriculture. The stainless steel variant of thimbles stands out due to its ability to maintain integrity even when exposed to saltwater, chemicals, and high mechanical loads, offering long-term protection and superior performance.

Why are stainless steel thimbles needed?

Stainless steel thimbles are needed in any situation where a wire rope is looped to create a fixed eye, especially when that loop is part of a load-bearing system. Without stainless steel thimbles, the rope itself must bear the brunt of the contact forces, which can lead to internal strand separation, fraying, and eventual failure. By incorporating a thimble into the loop, the load is distributed evenly across a rigid, shaped surface, significantly reducing the chance of damage or structural weakening.

Stainless steel thimbles are particularly crucial in marine and offshore applications. The high salinity of seawater can cause rapid corrosion in standard materials, compromising rope performance and safety. Stainless steel, on the other hand, resists this corrosion and maintains its structural integrity even after prolonged exposure. This makes stainless steel thimbles essential for sailing, mooring, anchoring, and offshore lifting systems.

In construction and infrastructure projects, stainless steel thimbles help ensure the reliability of cable systems used in cranes, hoists, and suspension bridges. Their ability to protect the rope from stress concentration points means fewer breakdowns and less maintenance over time.

Industrial and heavy machinery operations also benefit from stainless steel thimbles, as they offer dependable reinforcement for ropes used in high-tension systems such as mining winches, overhead lifting equipment, and conveyor mechanisms. In agricultural and outdoor applications, stainless steel thimbles provide long-lasting protection for fencing systems, livestock enclosures, and cable-secured load points, all while withstanding sun, rain, and temperature fluctuations without degrading.

Whether above ground, underwater, or in extreme climates, the need for stainless steel thimbles is clear: they are indispensable for preserving rope integrity and extending the lifespan of cable-based systems in safety-critical environments.

Types of stainless steel thimbles we offer

Stainless steel thimbles come in several forms, each developed to match a specific set of technical and environmental demands. At Global Rope Fittings, we supply a full spectrum of solutions to ensure you always have the right thimble for your application.

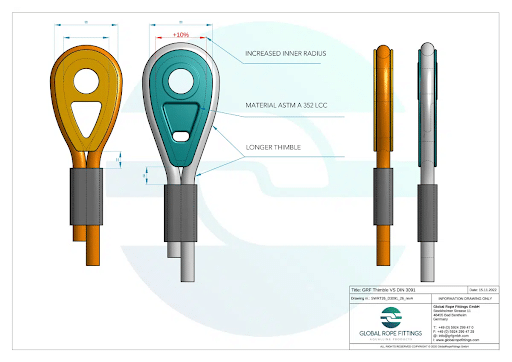

Solid heavy duty wire rope stainless steel thimbles

- Designed for extreme loads and high-tension applications.

- Ensures maximum rope protection in all environments.

Wire rope stainless steel thimbles and clamp sets

- Combines wire rope clamp and thimble for a complete loop termination.

- Prevents rope slippage while reinforcing loop strength.

Custom rope stainless steel thimbles

- Tailored designs to meet specific project requirements.

- Available in different materials – such as stainless steel – and sizes for unique applications.

Everyone of our stainless steel thimbles we supply is subjected to rigorous quality checks and meets international standards for safety and performance.

Why choose Global Rope Fittings for your stainless steel thimbles?

At Global Rope Fittings, we specialize in manufacturing high-performance stainless steel thimbles, designed for strength, durability, and reliability in demanding applications.

We understand that not every project has the same requirements, which is why we offer customizable options in both product design and order volume. Whether you need a single custom component or thousands of identical thimbles for a large-scale installation, we have the production capabilities and technical expertise to deliver on time and of quality.

Our commitment to quality begins with sourcing only premium-grade stainless steel and continues through every stage of production, from precision forming and finishing to final inspection. All our stainless steel thimbles are tested against strict performance metrics, ensuring they function reliably under pressure and meet industry standards for load-bearing hardware.

When you work with Global Rope Fittings, you gain a partner who understands the full lifecycle of a rigging system and how a single well-made thimble can make all the difference.

<Discover a selection of projects where our products have been adopted>

FAQs about stainless steel thimbles

What are stainless steel thimbles used for in wire rope assemblies?

Stainless steel thimbles are used to reinforce and protect the eye or loop of a wire rope, particularly in applications where corrosion and high tension are concerns. They help maintain the shape of the loop and reduce wear from contact with hardware such as shackles or hooks.

Can stainless steel thimbles be used in saltwater environments?

Yes, stainless steel thimbles are specifically designed to perform well in saltwater and marine environments. Their corrosion-resistant properties make them ideal for use on ships, docks, mooring systems, offshore rigs, and sailing equipment.

What is the difference between a stainless steel thimble and a galvanized thimble?

The main difference lies in corrosion resistance. Stainless steel thimbles are made from solid stainless material, offering long-term protection in aggressive environments. Galvanized thimbles have a protective zinc coating, which provides moderate corrosion resistance but is less durable over time, especially in marine or chemical settings.

How do I know which stainless steel thimbles are right for my rope?

Choosing the right thimble depends on the rope diameter, the expected load, and the environmental conditions. It’s essential that the thimble fits the rope snugly to ensure proper load distribution and avoid slippage or damage. For critical or custom applications, it’s best to consult a rigging specialist.

Do you provide custom stainless steel thimbles?

Yes, Global Rope Fittings offers custom-engineered stainless steel thimbles. Whether you need a specific size, enhanced load capacity, or compatibility with unique rigging systems, we can produce thimbles to match your exact project needs.

Are your stainless steel thimbles certified?

All of our stainless steel thimbles are manufactured to meet or exceed relevant industry standards. Certification and test documentation can be provided upon request, particularly for use in lifting, offshore, or safety-critical applications.

Can stainless steel thimbles be reused after disassembly?

Stainless steel thimbles can often be reused, provided they show no signs of deformation, cracking, or corrosion. However, in safety-sensitive environments, it’s always recommended to inspect them thoroughly or replace them to maintain full system integrity.

Contact us for stainless steel thimbles

Looking for high-quality stainless steel thimbles? Whether you need standard, heavy-duty, or custom options, we have the right solution for your application. Get in touch with our experts for tailored recommendations and product guidance.