What are turnbuckles?

Turnbuckles, also known as tensioners or strain adjusters, are mechanical devices used to regulate the tension and length of cables, wire ropes, or rods. They consist of an open or closed body with two opposing threaded eyelets, one with a left-hand thread and the other with a right-hand thread. By rotating the turnbuckle body, the tension in the connected cables can be increased or decreased, making them a crucial component in load-bearing and structural applications. There are two types of turnbuckles:

1. Standard Turnbuckles: Equipped with hooks, eyes, or jaw ends for various connection types. Both ends are threaded. Ideal for general tensioning applications.

-

- Application: Used in hoists, bridge structures, masts, and architectural cable systems.

-

- Advantage: Usually provided with hooks, eyes, or sleeving on both ends. Offers an easy setup.

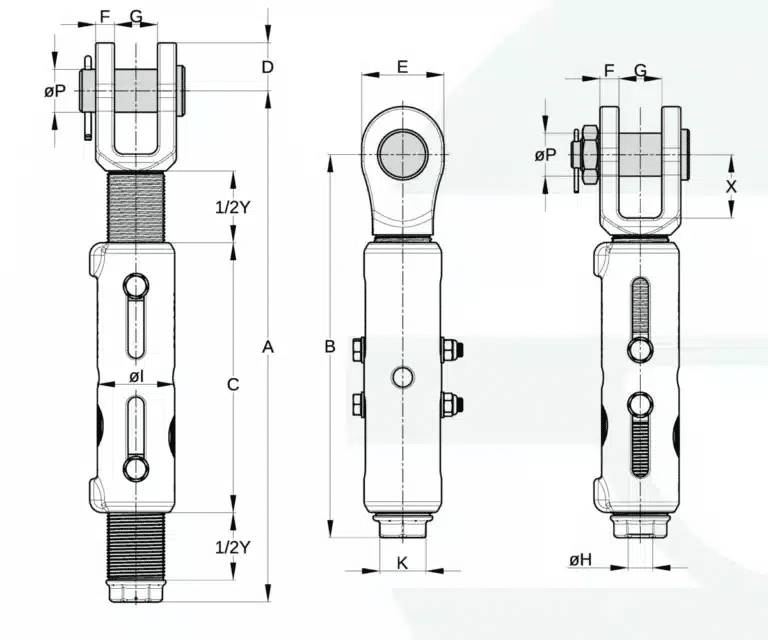

2. Turnbuckle Sockets: A specialized version of turnbuckles where one side is equipped with a socket connection. This means that the wire rope attaches directly into the socket. This turnbuckle system has high modularity where individual components can be easily replaced or reconfigured without the need to alter the entire system. Moreover, in comparison with the standard turnbuckles, turnbuckle sockets allow for significantly more accurate tension adjustment.

-

- Application: Specifically used in heavy-duty wire rope systems where precision tensioning is required for a sturdy and permanent connection, such as in bridges, cranes and large lifting installations.

-

- Advantage: A turnbuckle socket provides a stronger and more durable connection than a standard turnbuckle with screw eyes or hooks.

Using turnbuckles: how it works

If you’ve ever wondered how to use turnbuckles, the process is relatively simple. By rotating the turnbuckle body, the attached cables, wire ropes or rods are either drawn together or pushed apart, adjusting the tension accordingly. How to tighten a turnbuckle depends on the application, but using a wrench or hand-tightening the barrel is a common method.

Why choose our turnbuckles?

Our AqualLine turnbuckles are designed with precision and durability in mind (‘Designed to Perfection’), focusing on:

- Strength & Load Capacity: Engineered to withstand high-tension forces and extreme conditions.

- Efficiency: Easy to adjust and install, allowing for precise tensioning.

- Versatility: Available in different configurations for a wide range of applications.

- Safety: Manufactured according to strict industry standards for secure load management.

Take a look at our products, including turnbuckles

Applications of turnbuckles

Turnbuckles play a vital role in various industries and projects that require secure and adjustable tensioning solutions:

- Lifting & Rigging Systems

- Used in cranes, hoisting mechanisms, and load-bearing structures.

- Ensures safe and controlled lifting operations.

- Bridge & Structural Engineering

- Provides stability in suspension bridges and tensioned cable systems.

- Maintains structural integrity under fluctuating loads.

- Architectural & Decorative Cable Systems

- Used in modern architecture for tensioned cable railings and facades.

- Ensures structural stability.

- Offshore & Marine Applications

- Found in mooring systems, rigging on ships, and platform bracing

- Ensures secure and adjustable tensioning in harsh sea conditions.

- Energy & Utility Infrastructure

- Used in powerline guying and pipeline anchoring.

- Critical for maintaining alignment and load distribution across long spans.

- Forestry & Cable Logging

- Integral to skyline systems and slope-based extraction rigs.

- Allows precise control over long cable spans in rugged terrain.

Different sizes turnbuckles

Turnbuckles come in a variety of sizes to accommodate different tensioning needs. Choosing the right size turnbuckle depends on load capacity, thread type, and intended use.

Turnbuckles: safety & standards

When using turnbuckles in load-bearing applications, following proper safety guidelines is essential. Ensuring that the turnbuckle size matches the load requirement and regularly inspecting for wear and corrosion can prevent accidents. Many industries adhere to turnbuckle safety wire regulations to ensure secure fastening.

Why Global Rope Fittings for turnbuckles?

At Global Rope Fittings, we provide high-performance turnbuckles designed to meet the toughest industry demands. When you choose us, you’re choosing:

- Superior Materials: Made from stainless steel, galvanized steel, or high-strength alloys.

- Precision Engineering: Crafted for reliable tensioning in critical applications.

- Custom Solutions: Bespoke turnbuckles tailored to unique project specifications.

- Proven Performance: Rigorously tested for strength, safety, and longevity.

FAQs about turnbuckles

What’s the difference between standard turnbuckles and turnbuckle sockets?

Standard turnbuckles are equipped with common end fittings such as eyes, hooks, or jaws, and are typically used in general tensioning applications like rigging, fencing, or suspension systems. A turnbuckle socket, on the other hand, is a more specialized version where one end is designed to connect directly to a wire rope via a fitting. This type of turnbuckle sockets offer a more secure and permanent connection and is often used in demanding structural or lifting applications like cranes, bridges, or heavy-duty tension assemblies.

Are turnbuckles adjustable while under load?

Turnbuckles are designed to allow for tension adjustments, but adjusting them under full load is not always recommended. In many cases, especially with high-tension applications, adjustments should be made when the system is partially or fully unloaded to avoid excessive strain or damage to the threads. In critical applications, locking mechanisms or safety wires may be added to prevent unintentional movement after tensioning.

Can turnbuckles be reused?

Yes, turnbuckles can be reused, provided they remain in good condition. Regular inspection is key; look for signs of thread wear, corrosion, bending, or cracking. In load-critical applications, any damaged or heavily worn turnbuckle should be replaced immediately to ensure safety and reliability. Proper lubrication of the threads can also extend the service life of a turnbuckle used in environments with high exposure to the elements.

What material is best for turnbuckles?

The ideal material depends on the application environment. Stainless steel turnbuckles are often preferred in marine or outdoor settings due to their resistance to corrosion. Galvanized steel turnbuckles are more economical and offer good durability for general-purpose use. In high-load industrial environments, turnbuckles may also be made from alloy steel or feature special coatings to enhance performance under stress and prevent surface degradation.

How do I choose the right size turnbuckle?

Selecting the correct turnbuckle size involves considering the load capacity, the diameter of the wire rope, cable or rod being used, and the level of tension required. The thread size, length of adjustment, and type of end fittings should all match the specific requirements of the project.

Is there a standard for turnbuckle safety?

Yes, there are several industry standards and guidelines that govern the safe use of turnbuckles, especially in load-bearing or structural applications. These include recommendations for working load limits, inspection intervals, and installation practices. Some industries also require safety features such as lock nuts, safety wires, or pinned clevis ends to prevent loosening over time. Adhering to recognized standards ensures not only the safety of the installation but also the long-term reliability of the turnbuckle in its intended environment.

Contact us for turnbuckles

Need reliable turnbuckles for your project? Whether you require standard tensioning hardware or a custom turnbuckle socket, Global Rope Fittings is here to assist. Contact our experts today for tailored recommendations and high-quality rigging solutions.

Get in touch with us for more information about turnbuckles